Categories

Categories

ME 20 - EDGE BANDER

Product Description

Model: ME 20

Machine Features:

- Stable, steady, with constantly maintained adjustments, thanks to the stainless steel single-block base

- Upper protection device specifically intended to allow an easy access to the operating units

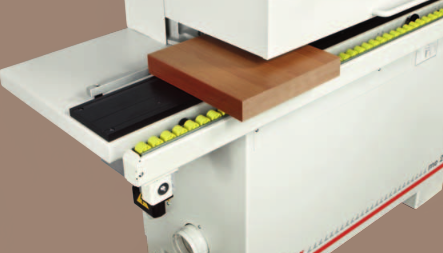

- High-precision panel feed on a friction-free worktable with rollers,which facilitate the sliding, by means of a top feeder with highadherence toothed belt

- Top quality edge banding with automatic positioning of all operating units synchronised with presser lifting and based on the panel height

- Easy and immediate edge thickness adjustment using a numeric readout on the infeed guide

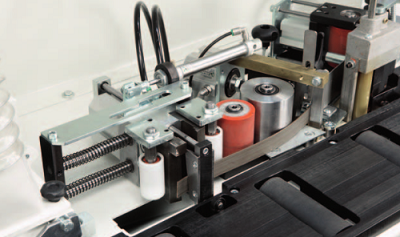

Practical edge loading and gluing unit

Edges in rolls are loaded automatically and cut precisely to size with a cutter. The glue is heated rapidly and evenly by the resistances located in both the glue pot and inside the glue spreader roller. With the PLC control it is possibile to maintain the temperature set constant even when the machine is in stand-by mode. Two rollers press the edge evenly and efficiently onto the panel. The pressing unit position is comfortably adjustable from the machine front side.

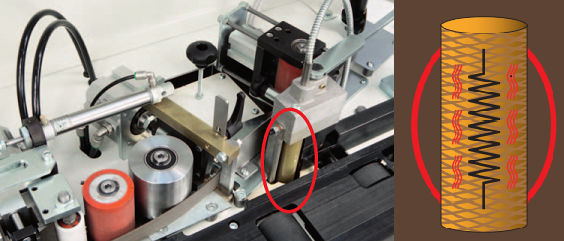

Extremely precise end cutting unit

Made of solid steel it guarantees

a clean, precise cut on the leading and trailing edges of the panel.

Referencing is done directly from the panel and there is therefore noneed for adjustment.

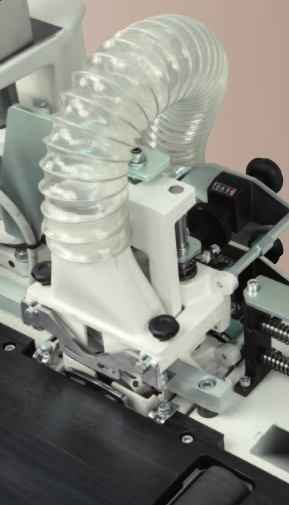

Perfect trimming unit finishing.

The unit has chromed plated,copiers which are bearing mounted to ensure smooth and “softened”panels feed so as to avoid any scratch due to friction on the panelsthemselves, particularly on those upgraded.

The control panel located on the front of the machine is used to control all the machine’s functions, quickly and intuitively. With the PLC it is possible to easily and comfortably exclude the shear and the end cutting unit to allow also edge banding with wooden strips of the maximum thickness of 5 mm.

Maximum panel height 50 mm

Technical Data

|

Thickness of rolled edges |

0,4 ÷ 2mm |

|

Max. thickness of edges in strips |

5mm |

|

Min. ÷ max. panel height |

12 ÷ 50mm |

|

Min. panel length/width |

180/65mm |

|

Panel feed speed |

6 6 |

Advantages

Fast set-up: glue is heated rapidly and evenly by the resistances located in both the glue pot and inside the glue spreader roller. Practical gluing unit. Two rollers press the edge evenly and efficiently onto the panel. The pressing unit position is comfortably adjustable from the machine front side. Always clean, precise cut on the leading and trailing edges of the panel assured by the pneumatic end cutting unit. Edge trimming top finishing with the trimming unit operating at a cutting speed of 12.000 rpm. Total control of all the machine’s functions, quickly and intuitively. With the PLC it is possible to easily and comfortably exclude the shear and the end cutting unit to allow also edge banding with wooden strips of the maximum thickness of 5 mm.

Loading... Please wait...

Loading... Please wait...