Categories

Categories

ME 25 - EDGE BANDER

Product Description

Model: ME 25

THE INNOVATIVE AUTOMATIC EDGE BANDING MACHINE FOR CRAFT JOINER’S SHOPS

Machine Feautures

- Stable, steady, with constantly maintained adjustments, thanks to the stainless steel single-block base

- Easy-to-use in all working conditions with the control panel on the machine front side

- High-precision panel feed on a high-adherence belt with a top presser fitted with rubber wheels

MULTIFUNCTION AS EXCELLENCE

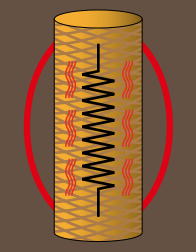

Practical edge loading and gluing unit. Edges in rolls are loaded automatically and cut precisely to size with a cutter. The glue is heated rapidly and evenly by the resistances located in both the glue pot and inside the glue spreader roller. With the PLC control it is possibile to maintain the temperature set constant even when the machine is in standby mode. Two rollers press the edge evenly and efficiently onto the panel.

Glue is uniformly spread and always at themaximum working temperature even on the panels of the maximum working height, thanks to the spreading roller with electrical resistance inside.

Absolute precision provided by the end cutting unit, powered by an independent motor that cuts off precisely at 90°, with a blade, any edge excess. Using the numeric readout the blade projection can be adjusted according to the thickness of the edge to be applied.

Top-class finishing with the trimming unit, including 72 mm diameter cutters and pad copiers for perfect alignment with the panel. These cutters are designed for straight or radial trimming of any kind of edge, whether it is thick or thin, made of PVC, ABS, melamine or wood.

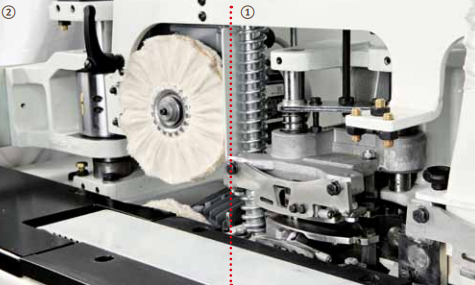

1. Superb finishing quality thanks to the edge scraping unit (optional) with a very strong structure guaranteed in any working condition. Precision positioning is assured by pad copiers. With a practical device for unit exclusion when it is not in use.

2.Excellent edge cleaning-polishing with the (optional) brushing unit with two independent motors, tilted and vertically adjustable.

Technical Data

|

Worktable dimensions |

2600 x 530 |

mm |

|

Minimum panel length/width |

190/65 |

mm |

|

Worktable height |

904 |

mm |

|

Thickness of rolled edges |

0,4 ÷ 3 |

mm |

|

Min. ÷ max. panel thickness |

16 ÷ 50 |

mm |

|

Feed speed |

7 |

m/min |

Loading... Please wait...

Loading... Please wait...