Categories

Categories

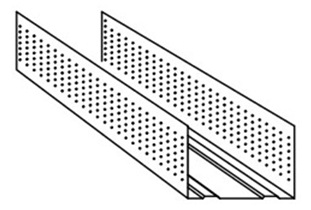

TRACK- ROLL FORMING LINE FOR TRACK PROFILE

Product Description

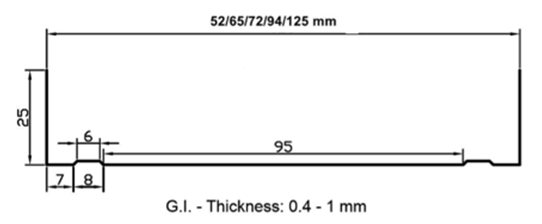

FOR TRACK PROFILE

Technical Parameters:

Material Parameter

Material: Galvanization Steel

Thickness:0.4-1.0 mm

Material Width: For track 52mm :99 mm

65mm : 112 mm -72 mm : 119 mm

94 mm :141 mm -125 mm : 172 mm

Work piece drawing

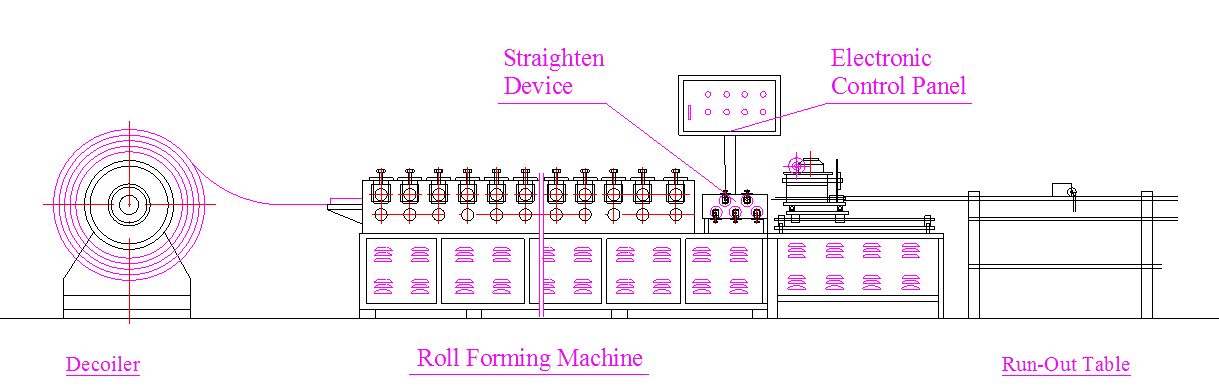

Production Process

Uncoil----Roll Forming----Cut-Off after sizing----Final product

Machine’s Composition

Machine’s Composition

Expand Manual De-coiler (1 set)

- Max. Load capacity: 1500kgs

- Inner diameter: 450-500mm

- Outer diameter: 1400mm

- Max. Width: 500~600mm

- Expansion to tighten coil by manual

This de-coiler is de-coiled attractively by roll forming machine and expanded or shrunk by manual operation (de-coiler can be adjusted to expand or shrink by revolving de-coiler center screw). The brake belt can control the speed of de-coiler.

Roll Forming Machine

Roll Forming Machine

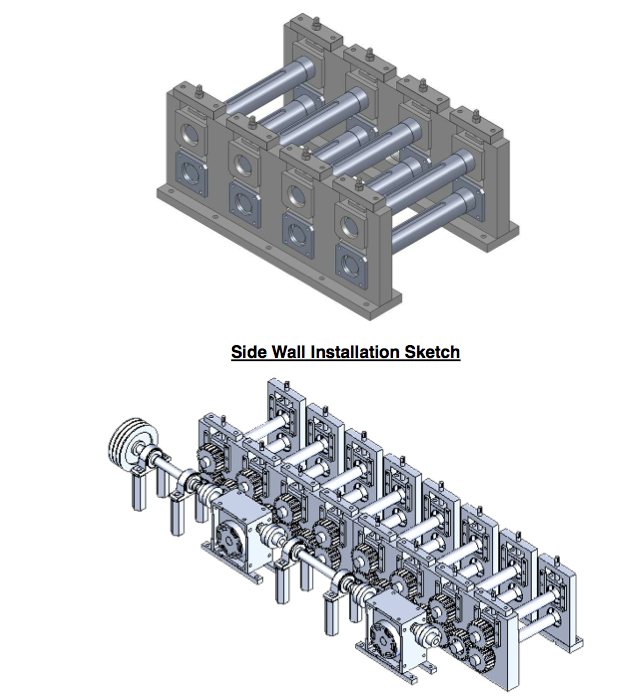

- Forming steps: 13 stations with entry guide stand. Each station consists of 2 sets of roller around 2 shafts one up and one down.

- High class and precise welding treatment assemble Main machine base.

- Transmit system: chain and gear.

- Main machine motor: 3KW

- Roll forming speed: 8 M/Min

- Roller’s specification: GCr15

- Quenching hardness: HRC55-57

- Shaft: 45# steel with heat treatment; diameter: 42mm.

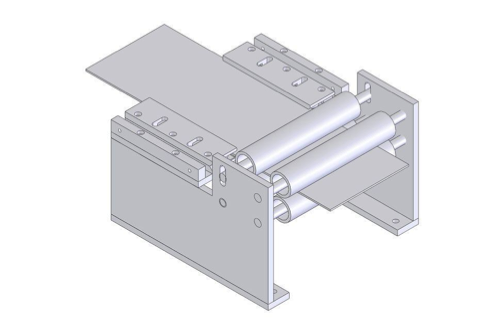

Roll forming Machine: It is composed of feed guide plate, roll forming machine, and straighten device.

1) Feed Guide Plate: It is used to fix the left-or-right place of the material plate. If the size of product after processing is not up to requirement, operators can adjust it.

2) Roll forming Machine: It is used to press the material plate to the shape according to the drawing, composed of 15 groups of rollers. Its rollers are fixed, vertical adjustable. It is driven by motor, decelerated by speed-reducer, power-transferred by chains and gears.

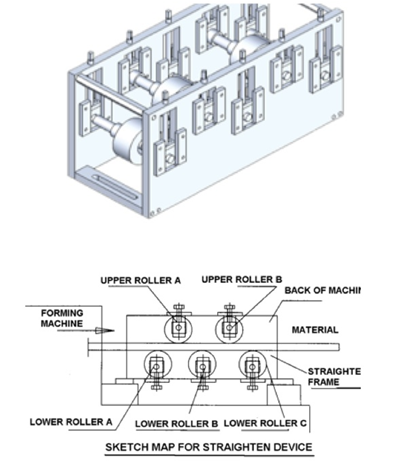

3) Straighten Device: It is composed of 5 groups of straightening rollers (two upper and three lower). It is set at the back of the roll forming machine to straighten the product after roll-formed.

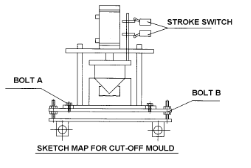

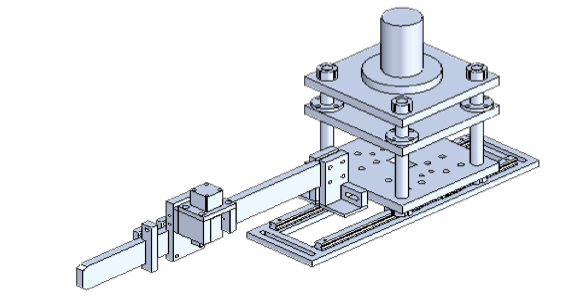

4) Hydraulic Cut-off System 1 set:

- Material of the cut-off blade: Cr12

- Quenching hardness: HRC60-62

- Clean cut with burring

- Hydraulic oil pump power: 4KW

- Cut-off blade (with burs): 5 set

- Hydraulic oil station supplying power to system

Product run-out table

- Table lengths:4000 mm

- Width:100 mm

Run-Out Table: It is used to support profile after roll-formed and fix the Length of the profile. Run out table consists of Length control device.

Length Control Device: it’s pneumatic cylinder fixed on the support table on the correct position to give the required length, when the profile touch the stopper the sensor give order to the roll forming machine to stop and also to start the pneumatic cutter, once it cut the profile with required length, the pneumatic cylinder will move and release the profile from the support table.

Electric Control Panel: It is used to central-control and supply power, generally fix on the top of the machine.

Loading... Please wait...

Loading... Please wait...