Categories

Categories

- Home

- Roll Forming Machines

- Guard Rail Forming Line

- W300- GUARD RAIL ROLL FORMING MACHINE

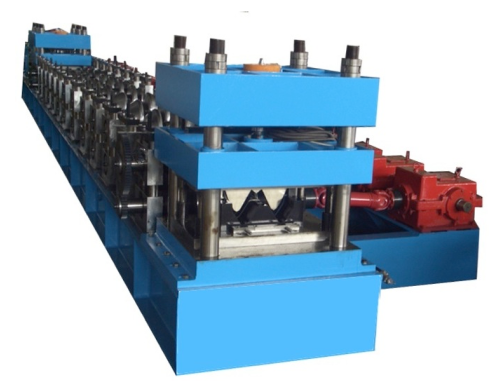

W300- GUARD RAIL ROLL FORMING MACHINE

Product Description

GUARD RAIL ROLL FORMING MACHINE

Model: W300

CONTAIN

1 – WORK PIECE DRAWING & SAMPLE

2 – MACHINE LAYOUT & LINE PROCESS

3 – TECHNICAL SPECIFICATION

4 – MACHINE PHOTOS

Work piece drawing:

Work piece Samples:

Machine Lay out and Line Process:

Transmission System Lay out:

Technical Specification

1 ‐ Hydraulic de‐coiler

Single unrolling machine, one side can put material Adopt automatic hydraulic system

- Coil weight (Max): 3000kg

- Coil dia. (Max): 1600mm

- Oil cylinder dia.: 1200mm

- Working pressure: 10mpa

- Coil Width (Max.): 500mm

2‐ Feeding, Leveling

Feed into unit oriented wheel (can right and left adjust) Into feeding roller,

DIA. is ¢180mm, material 45# steel, quenched 48°‐52°, chromed Leveling is three

roller above and four roller below, quenched and chromed

3‐ Punching (can right and left adjust)

Using hydraulic punching oil cylinder

DIA: ¢140mm

Working pressure: 20mpa

Mould material: Cr12 quenched 58°‐62°

Hydraulic power: 7.5kw

Size: 1.5m long*1.1m wide*1.2m high

4 ‐ Roll Forming Machine

1. Matching material: according to the drawing

2. Material thickness range: 2.0‐3.0mm

3. Main motor power: 30 KW

4. Forming speed: 2‐4m/min (include the punching and cutting time)

5. Hydraulic station power: 22KW

6. Quantity of stands: about 13

7. Shaft Material and diameter: ¢80 mm, material is 40CR

8.Material Of The Stations: pig iron

9.Tolerance: 3m+‐1.5mm

10.Way Of Drive: Gearbox

11. Controlling system: PLC

12.Material of forming rollers: Gcr 15, coated with chromed treatment

5‐ Cutting Machine

Hydraulic cut

Knife material: Cr12, quenched 58°‐62°

Oil cylinder dia.: 250mm

Working pressure: 30mpa

Working journey: 80mm

6‐ The Outside size and waight:

L*W*H 12m*1.5m*1.2m

Total weight: about 8 Tons

7‐ Run out table

Jointed by 60mm*40mm tube (can be adjusted to up and down)

Size:1.5m long*0.8m wide*0.6‐1m high (can be adjusted)

8‐ Control system

- Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (depend on the customer)

- Automatic length measurement: one unit tooling of length measuring Which is lightly pressed on the surface of the steel sheet; the tolling will Roll with the moving speed of the steel sheet and then sense to measure Its length.

- Automatic quantity measurement

- Computer used to control length & quantity. Machine will automatically

- Cut to length and stop when required quantity is achieved Length inaccuracy can be amended easily.

- Control panel: Button‐type switch, LED display length and quantity

- Unit of length: millimeter and inch (switched on the control panel)

Machine Photos:

Loading... Please wait...

Loading... Please wait...